Aerogel is a class of highly porous, lightweight materials known for their low density and excellent insulating properties. Their biocompatibility largely depends on the type of aerogel and its intended application, especially in biomedical fields. Here’s an overview of their biocompatibility:

1.Material Composition:

Silica Aerogels: Silica-based aerogel is among the most widely studied and are generally considered biocompatible. Silica is a natural substance that is non-toxic and typically well tolerated by the human body, making it a good candidate for biomedical applications such as drug delivery, tissue scaffolds, and wound dressings.

Polymer Aerogels: These are typically made from organic materials like polyurethane or polyimide. Depending on the chemical composition, these aerogel can be biocompatible, but they may need additional surface modifications to reduce toxicity or improve their interaction with biological systems.

Carbon and Metal Aerogels: Aerogel made from carbon or metals are generally less biocompatible compared to silica-based ones. However, certain modifications or coatings can improve their compatibility for specific applications.

2.Surface Modifications:

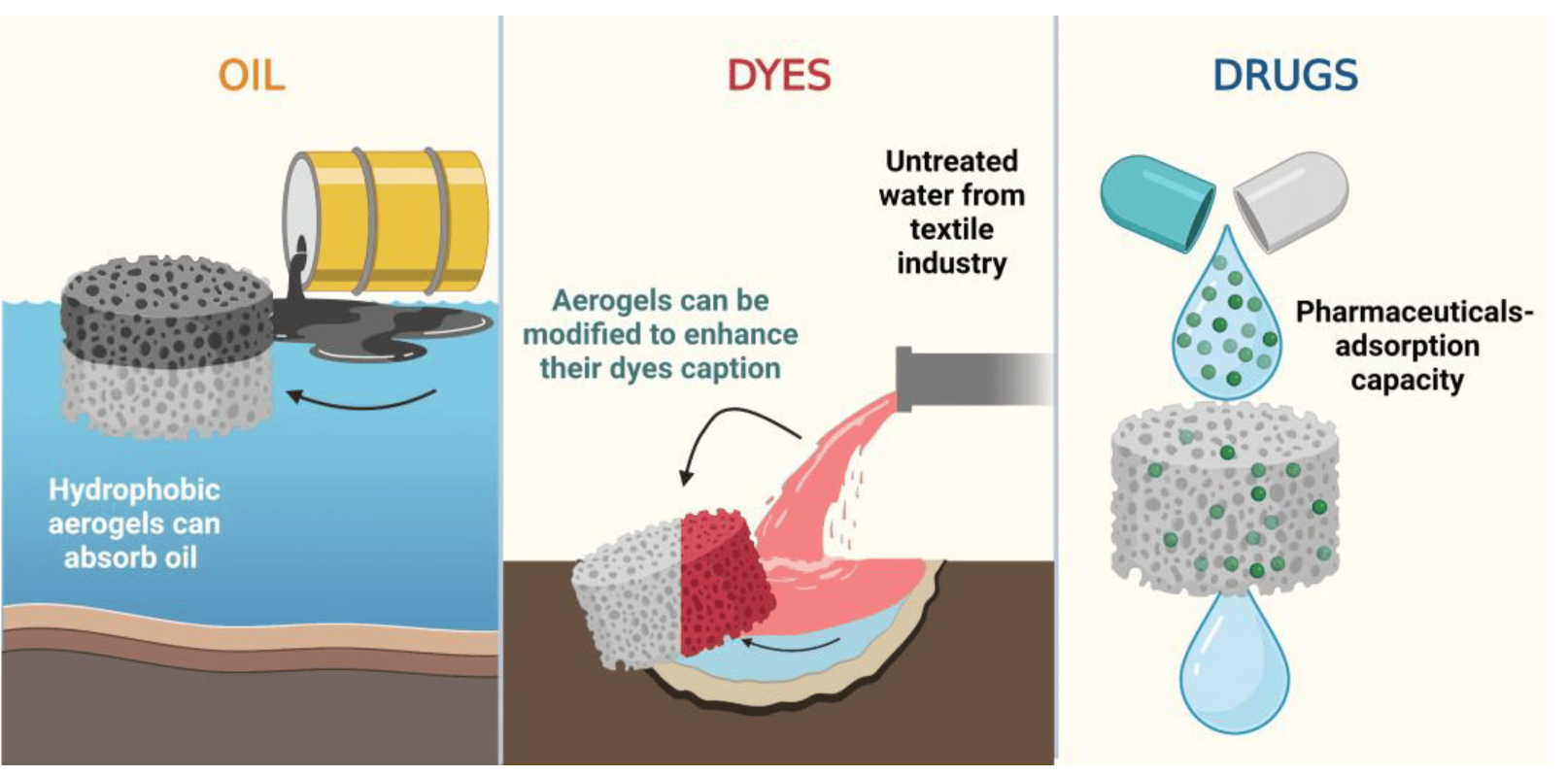

Aerogel can be surface-modified with bioactive molecules, which can enhance their interaction with cells and tissues. This makes them suitable for applications like scaffolding for tissue engineering, as the modified surface can promote cell adhesion, growth, and differentiation.

3.Applications in Medicine:

Drug Delivery: Silica aerogels are used in controlled drug delivery systems due to their high surface area and ability to hold large amounts of bioactive compounds. They can be engineered to release drugs in a controlled and sustained manner.

Wound Healing: Aerogel have been used as wound dressings due to their lightweight nature and their ability to absorb exudates while keeping the wound moist, promoting healing.

Bone and Tissue Engineering: Aerogel can serve as scaffolds for tissue engineering. Their high porosity mimics the extracellular matrix of tissues, which is essential for cell migration and nutrient exchange.

4.Toxicity:

When it comes to toxicity, silica aerogels have been shown to be non-toxic in vitro (in cell cultures) and in vivo (in animal studies), particularly when synthesized and modified properly. However, fine silica particles (such as those generated during aerogel production) may pose inhalation risks, and measures are required to minimize exposure to dust during manufacturing.

5.Challenges:

While aerogel hold great promise in biomedicine, there are still challenges related to their mechanical strength, degradation rate (in the case of biodegradable aerogel), and long-term stability in the body. Research continues to improve their properties for enhanced biocompatibility.

In summary, aerogel, particularly silica-based aerogels, exhibit a high degree of biocompatibility and are being increasingly explored for use in medical and biomedical applications. However, the specific application, material composition, and surface modifications play crucial roles in determining their biocompatibility and performance.