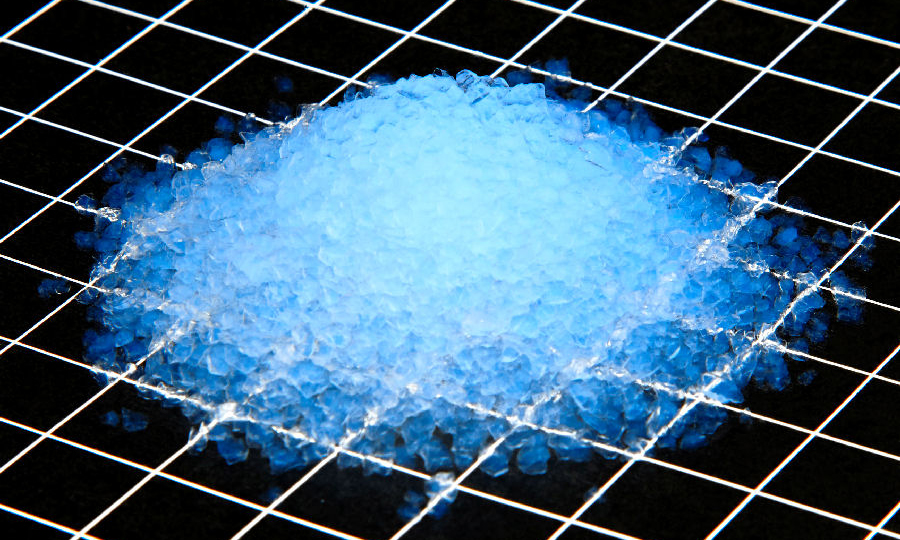

Aerogel is known for their remarkable ability to withstand high temperatures, primarily due to their unique structure and composition. Here are a few key reasons why aerogel can perform well under intense heat:

- Low Thermal Conductivity: Aerogel have an extremely low density with a porous structure, which makes them excellent insulators. The air trapped in their pores has very low thermal conductivity, which reduces heat transfer through the material.

- High Melting Points: Many aerogel is made from materials like silica, alumina, or carbon, all of which have relatively high melting points. This allows them to retain structural integrity even at elevated temperatures.

- Heat Resistance: Silica aerogels, in particular, can withstand temperatures up to 1000°C (1832°F) or higher, depending on the specific formulation and any additional coatings or treatments they might have received to enhance heat resistance.

- Porosity: The porous structure of aerogel means that they don’t contain much material that could absorb heat. Instead, heat is absorbed mostly by the air in the pores, which reduces the overall amount of energy transferred through the material.

Because of these properties, aerogel is used in a variety of high-temperature applications, such as insulation for spacecraft, thermal barriers in industrial settings, and even fire-resistant clothing.

Aerogel for Energy Applications

Aerogel is lightweight, porous materials with unique properties that make them highly suitable for a range of energy applications. Here are a few key areas where aerogels are being used or researched for energy-related purposes:

1. Thermal Insulation:

- Aerogel is excellent thermal insulators due to their low thermal conductivity. This makes them useful in applications where energy efficiency and heat retention are critical, such as in building insulation, clothing (e.g., NASA’s spacesuit insulation), and cryogenics. Their low density and high porosity reduce the heat transfer significantly, helping to minimize energy loss.

2. Energy Storage (Batteries and Supercapacitors):

- Aerogel is being explored as materials for energy storage devices like batteries and supercapacitors. The high surface area and tunable porosity of aerogel provide ample space for charge storage, which can potentially improve the performance of these devices. For example, aerogels can enhance the performance of lithium-ion batteries and supercapacitors by increasing their capacity, stability, and charge/discharge cycles.

3. Catalysis and Fuel Cells:

- Aerogel is also used in catalytic processes, particularly in fuel cells. Their large surface area and porosity allow for efficient catalytic reactions, which are essential for fuel cell efficiency. Aerogel can serve as a support for catalysts, improving their effectiveness in generating electricity from hydrogen or other fuels.

4. Solar Energy:

- Aerogel is being researched for their potential in improving solar energy systems, particularly in solar panels. Their transparency, low thermal conductivity, and high surface area make them ideal candidates for improving the efficiency of solar collectors by enhancing the capture and insulation of solar energy.

5. Gas Capture and Carbon Sequestration:

- Due to their high surface area and porosity, aerogel is also being studied for carbon capture applications. Aerogel can absorb large amounts of carbon dioxide, making them a promising material for mitigating greenhouse gas emissions in power plants or other industrial processes.

6. Energy-efficient Sensors:

- Aerogel can be used to create highly sensitive and energy-efficient sensors for detecting various gases, including environmental pollutants or hazardous chemicals. These sensors are often utilized in energy systems to monitor emissions or the efficiency of energy generation and consumption.

Challenges and Future Directions:

- Cost and Manufacturing: Although aerogel have a lot of potential, their high production cost and manufacturing complexity remain a challenge.

- Mechanical Strength: Some aerogels, particularly silica-based ones, can be brittle, limiting their applications in some energy systems where mechanical stress is involved.

The future of aerogel in energy applications seems promising, particularly as advancements in material science and manufacturing processes continue to lower costs and enhance their mechanical properties.