Boron Nitride (BN) has many applications because of its unique combination of properties — high thermal conductivity, electrical insulation, chemical inertness, and lubricity. Its use depends on its crystal form (hexagonal, cubic, etc.).

Applications of Boron Nitride

�� 1. Industrial and Engineering Applications

Lubricants:

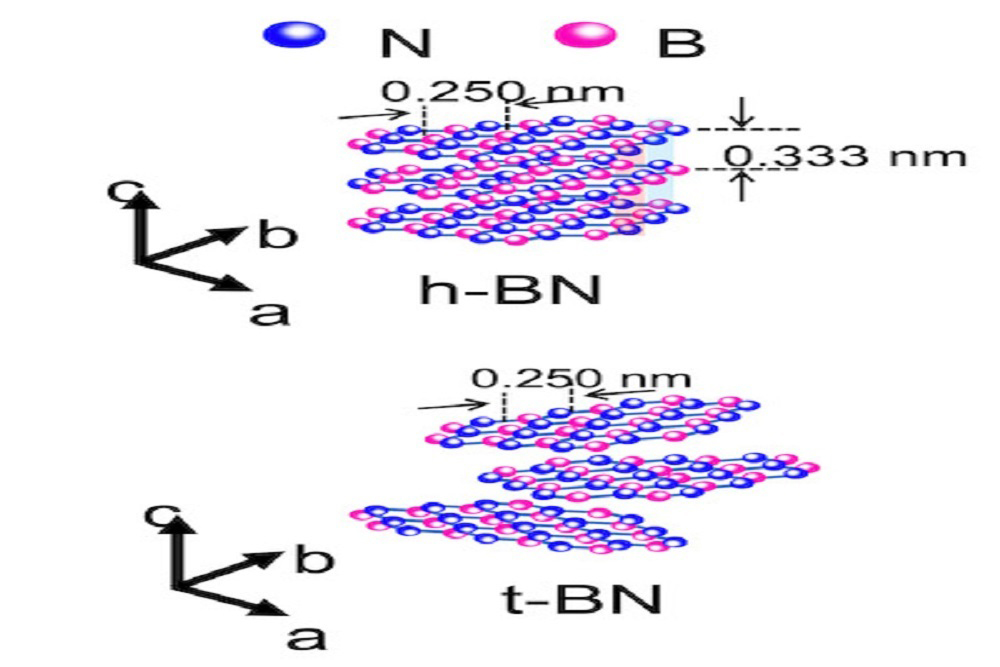

- Hexagonal Boron Nitride (h-BN) acts like “white graphite.”

- Used as a dry lubricant in high-temperature environments (up to 900 °C in air) where graphite oxidizes.

- Common in metal forming, glass molding, and aerospace components.

Protective Coatings:

- Boron Nitride coatings provide anti-stick, corrosion resistance, and electrical insulation.

- Applied on molds, crucibles, and dies for aluminum, magnesium, or zinc processing.

Thermal Management Materials:

- Boron Nitride’s high thermal conductivity and electrical insulation make it ideal for heat sinks, electronic substrates, and insulating fillers in polymers or adhesives.

�� 2. Electronics and Semiconductor Industry

Insulating Layers:

- Used in microelectronics as a dielectric layer due to its wide bandgap (~5.9 eV).

- Provides stable electrical insulation and thermal control.

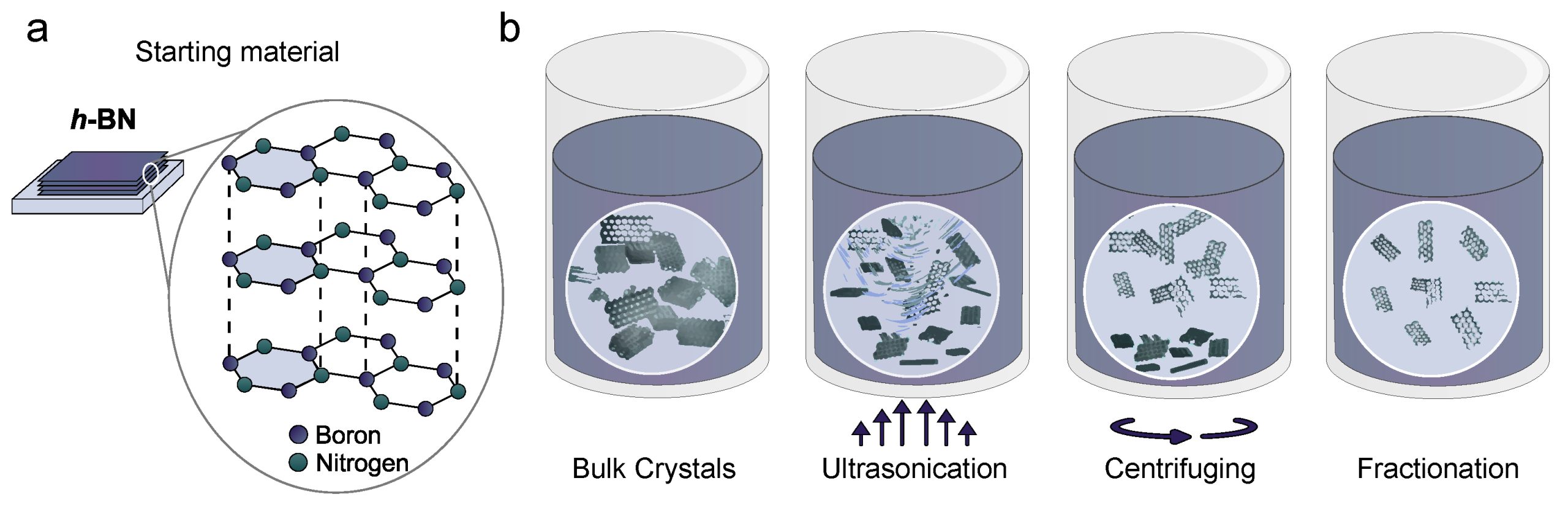

2D Materials (Hexagonal Boron Nitride nanosheets):

- Acts as an atomically flat insulating substrate for graphene and other 2D materials.

- Enhances carrier mobility and device performance in transistors and sensors.

Cubic Boron Nitride (c-BN):

- Second hardest material after diamond.

- Used for semiconducting devices, transistors, and power electronics due to thermal stability and high bandgap.

�� 3. Cutting Tools and Abrasives

Cubic Boron Nitride (c-BN):

- Extremely hard, stable at high temperatures.

- Used in grinding wheels, cutting tools, and machining ferrous materials (unlike diamond, which reacts with iron).

- Common in automotive, aerospace, and precision engineering.

�� 4. Ceramics and Composites

High-Temperature Ceramics:

- Boron Nitride ceramics are used for crucibles, nozzles, and insulating components in furnaces and reactors.

- Resist attack from molten metals, slags, and acids.

Composite Reinforcement:

- Boron Nitride nanotubes and nanosheets strengthen polymers, ceramics, and metal composites by improving thermal and mechanical properties.

�� 5. Aerospace and Defense

- Thermal barrier materials in spacecraft, satellites, and jet engines.

- Boron Nitride fibers and composites used for lightweight, heat-resistant structures.

�� 6. Cosmetics and Medical Applications

Cosmetics:

- Hexagonal Boron Nitride is used in foundations and powders for its silky texture, oil absorption, and light diffusion.

- Non-toxic and chemically stable.

Biomedical Uses (Emerging):

- Boron Nitride nanoparticles are studied for drug delivery, bioimaging, and antibacterial coatings due to biocompatibility.

��7. Other Applications

- Neutron shielding (due to boron’s high neutron absorption cross-section).

- Additives in plastics and rubbers to improve thermal conductivity and wear resistance.

- Lubrication in vacuum systems or space equipment where conventional oils fail.

Would you like me to organize these applications by Boron Nitride type (e.g., hexagonal, cubic, amorphous) for clarity?