Boron Nitride (BN) and Boron Carbide (B₄C) — two advanced ceramic materials often used for high-performance applications but with very different structures and properties.

1. Chemical Composition

Boron Nitride (BN):

Composed of boron (B) and nitrogen (N) atoms.

Boron Carbide (B₄C):

Composed of boron (B) and carbon (C) atoms.

2. Crystal Structure

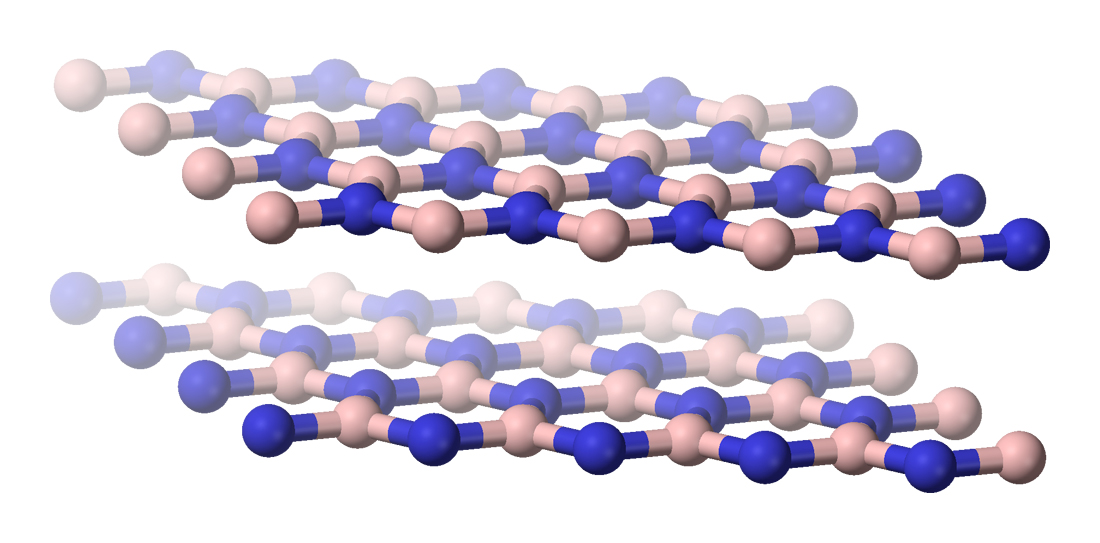

Boron Nitride (BN):

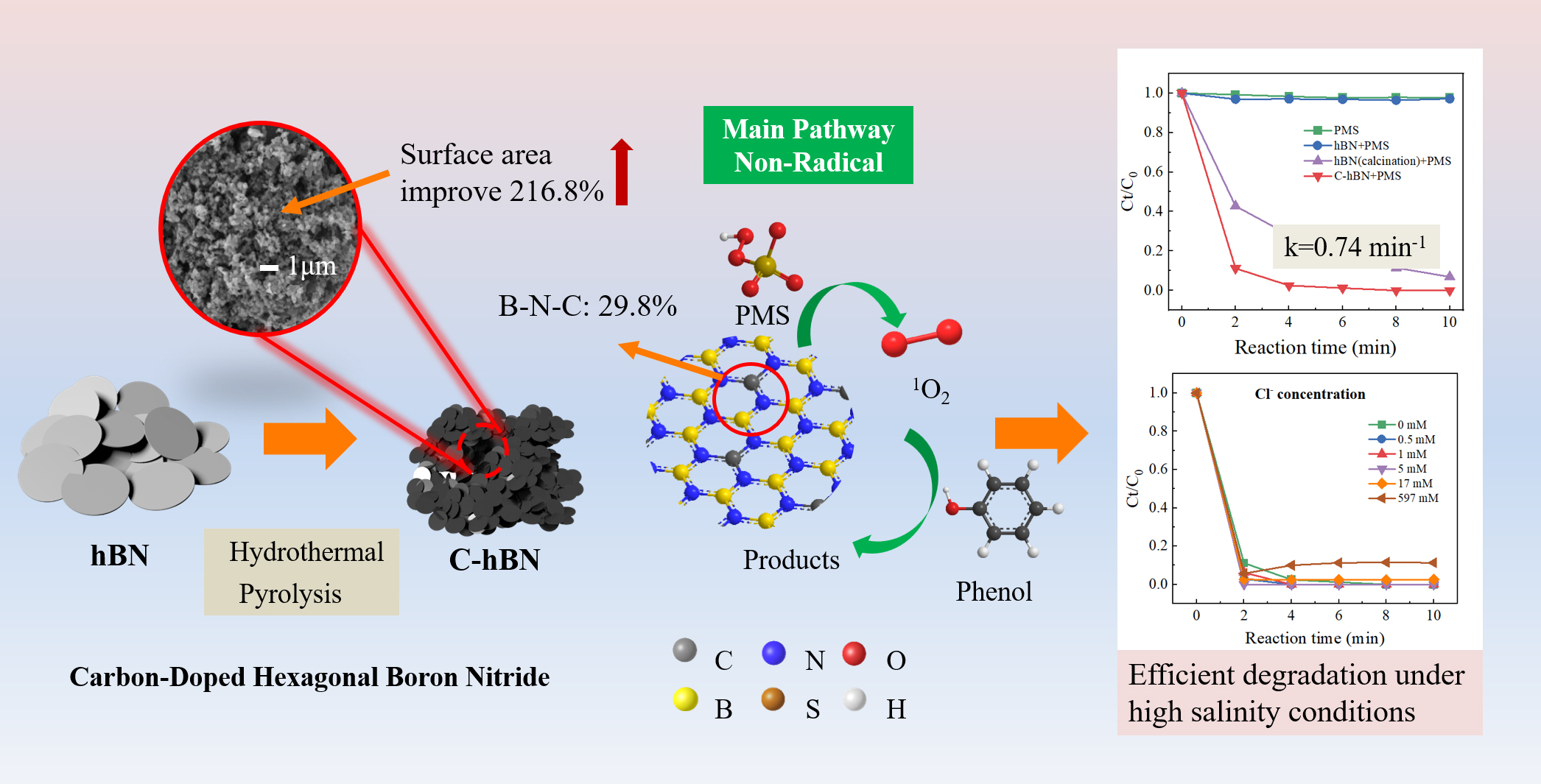

Comes in several forms, similar to carbon:

- h-BN (hexagonal BN): graphite-like, soft, lubricating

- c-BN (cubic BN): diamond-like, extremely hard

- w-BN (wurtzite BN): even harder than diamond in certain directions

B₄C:

Has a rhombohedral crystal structure, very hard and resistant to wear.

3. Hardness

Boron Nitride (BN):

- c-BN is the second hardest material after diamond

- h-BN is soft (like graphite)

B₄C:

One of the hardest known materials (ranking just below c-BN and diamond)

Hardness ranking (approx):

Diamond > w-BN ≥ c-BN > Boron Carbide > Silicon Carbide

4. Thermal Properties

Boron Nitride (BN):

- High thermal conductivity

- Excellent heat resistance (stable up to ~1000°C in air)

- Good thermal shock resistance

B₄C:

- Lower thermal conductivity than BN

- High melting point (~2450°C)

- Strong but poorer thermal shock resistance compared to Boron Nitride

5. Electrical Properties

Boron Nitride (BN):

Excellent electrical insulator, used in electronics and high-temperature insulators.

B₄C:

Semiconducting properties, slightly electrically conductive.

6. Chemical Stability

Boron Nitride (BN):

Chemically inert, resistant to most acids and bases.

B₄C:

Good chemical stability but reacts with strong oxidizers or hot concentrated alkalis.

7. Typical Applications

Boron Nitride (BN):

- Lubricants (h-BN, “white graphite”)

- High-temperature crucibles and furnace parts

- Electrical insulators

- Thermal management materials

- Coatings for metal casting

Boron Carbide (B₄C):

- Armor (bulletproof vests, tank armor)

- Abrasives (sandblasting, grinding)

- Neutron absorbers in nuclear reactors

- Wear-resistant materials

- Cutting tools (though less common than c-BN)

8. General Summary

| Property | Boron Nitride (BN) | Boron Carbide (B₄C) |

| Composition | B + N | B + C |

| Forms | Hexagonal, Cubic, Wurtzite | One main rhombohedral form |

| Hardness | Varies: soft (h-BN) to extremely hard (c-BN) | Very hard |

| Thermal Conductivity | High | Moderate |

| Electrical Conductivity | Insulator | Semiconductor |

| Chemical Stability | Very high | High |

| Main Uses | Lubricants, insulators, high-temp ceramics | Armor, abrasives, neutron absorption |