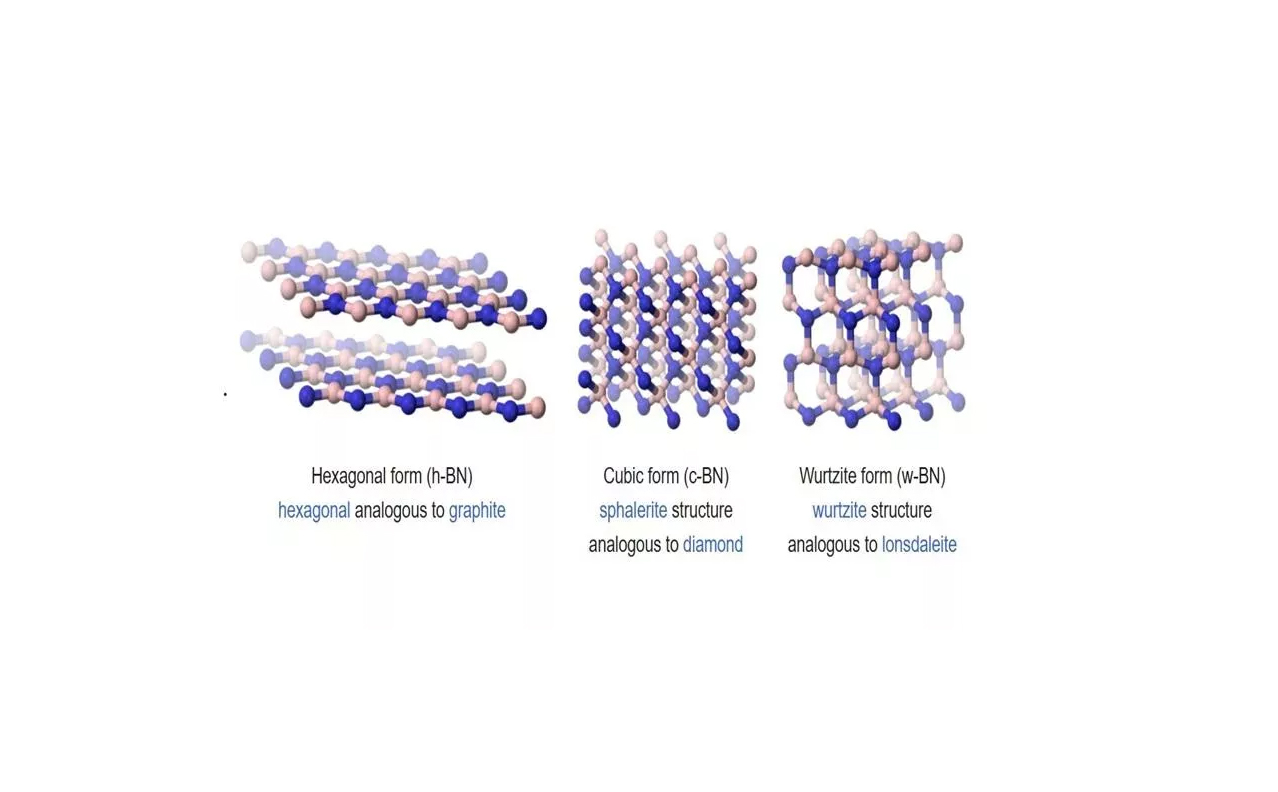

Boron Nitride is a chemical compound made of boron (B) and nitrogen (N) with the formula Boron Nitride(BN). It is a synthetic material with several crystalline forms, each with unique properties.

Pros of Boron Nitride:

1. High Thermal Stability

- Boron Nitride can withstand very high temperatures (up to ~900–1,500°C in air, higher in inert atmospheres) without significant degradation.

- Useful in high-temperature coatings, crucibles, and thermal management applications.

2. Excellent Thermal Conductivity

- Particularly in its hexagonal form (h-BN), it has high in-plane thermal conductivity while remaining electrically insulating.

- Ideal for heat dissipation in electronics without causing electrical shorts.

3. Electrical Insulation

- Boron Nitride is an excellent electrical insulator.

- Commonly used in electronics, semiconductors, and insulating components in high-voltage applications.

4. Chemical Inertness

- Resistant to chemical attack by acids, alkalis, and molten metals.

- Suitable for protective coatings and chemical-resistant components.

5. Lubricating Properties

- Hexagonal Boron Nitride has a layered structure similar to graphite, giving it excellent dry lubrication properties.

- Works under extreme temperatures and pressures where oils or greases fail.

6. Low Density and Lightweight

- Boron Nitride is relatively light, making it attractive for aerospace and advanced materials applications.

7. Radiation Resistance

- Stable under neutron radiation, making it useful in nuclear applications.

8. Versatility in Forms

- Available as powders, coatings, thin films, composites, and ceramics.

- Can be tailored for thermal, mechanical, or lubricating applications.

Cons of Boron Nitride:

1. Cost

- Boron Nitride can be expensive compared to conventional ceramics or lubricants, limiting its use in cost-sensitive applications.

2. Brittleness

- Like most ceramics, Boron Nitride is brittle and can fracture under mechanical stress, especially in its cubic or hexagonal crystalline forms.

3. Limited Mechanical Strength

- Its strength is lower compared to materials like boron carbide or silicon carbide.

- Not suitable for structural load-bearing components.

4. Processing Challenges

- High-purity Boron Nitride can be difficult to synthesize and process.

- Requires high-temperature sintering or chemical vapor deposition for high-performance applications.

5. Moisture Sensitivity (in some forms)

- Some Boron Nitride powders or composites can absorb moisture, which may affect certain applications, such as in electronics or high-temperature coatings.

6. Not a Metal Substitute

- Boron Nitride is electrically insulating; it cannot replace metals in conductive or structural applications.

Summary Table:

| Pros | Cons |

| High thermal stability | High cost |

| Excellent thermal conductivity | Brittle, low mechanical strength |

| Electrical insulation | Processing challenges |

| Chemical inertness | Moisture sensitivity in some forms |

| Lubricating properties | Not electrically conductive |

| Lightweight | Limited structural applications |

| Radiation resistant | |

| Versatile forms |