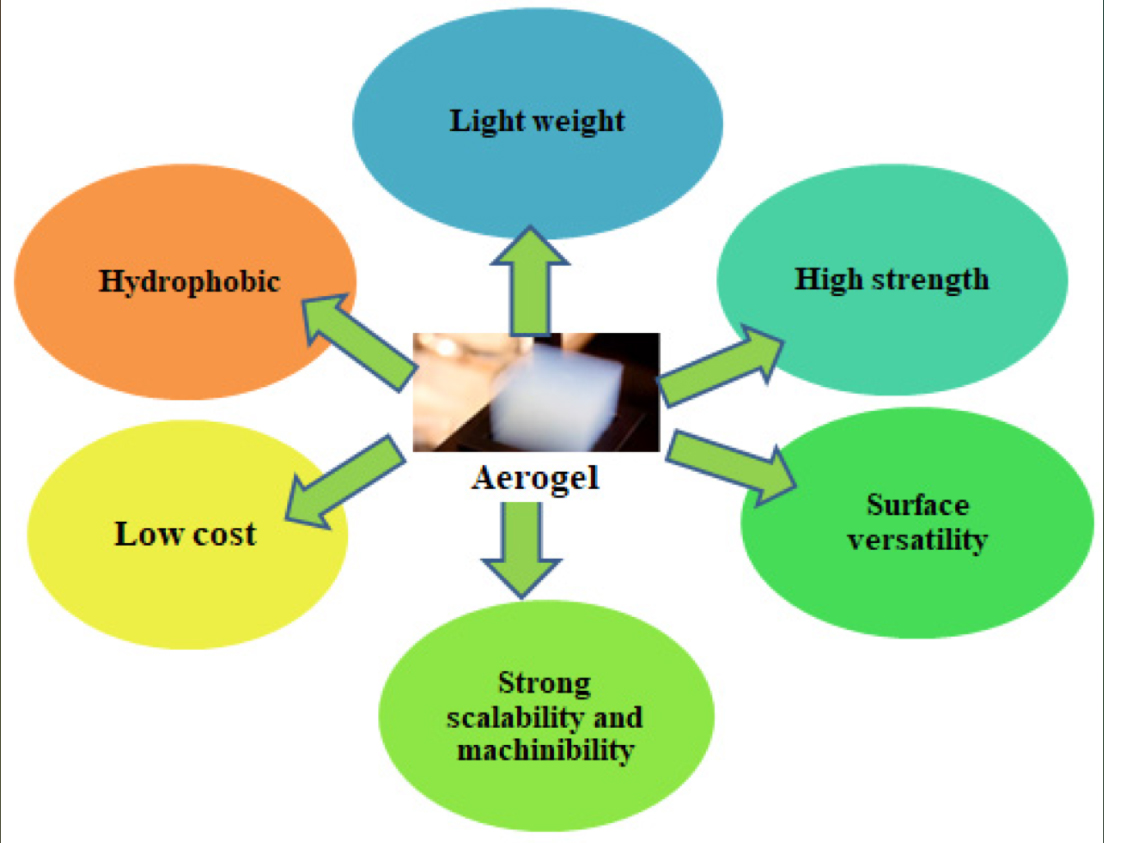

Aerogel is known for their remarkable properties, including low density, high surface area, and excellent insulation capabilities. When it comes to their chemical stability, it depends on the type of aerogel and the conditions they are exposed to. Generally, aerogel is chemically stable in a wide range of conditions, but their stability can vary based on the material used to make them.

Here’s a breakdown of some key points:

1.Silica Aerogel:

Chemical Stability: Silica aerogels is chemically stable in neutral and mildly acidic or basic environments. They resist most organic solvents, acids, and bases under normal conditions.

Limitations: They can react with very strong acids or bases, especially at elevated temperatures. Silica aerogels is also susceptible to degradation if exposed to high humidity over long periods, as they can absorb water and undergo hydrolysis, which could affect their structure.

2.Organic Aerogels (e.g., resorcinol-formaldehyde or polyimide):

Chemical Stability: Organic aerogels tend to have a lower chemical stability compared to silica aerogels. They are more prone to degradation when exposed to heat, moisture, or certain solvents.

Limitations: Organic aerogel may undergo oxidation or degradation at higher temperatures, especially in the presence of oxygen. Also, exposure to solvents and high humidity can cause them to lose their structural integrity.

3.Metal Oxide Aerogels:

Chemical Stability: Metal oxide aerogels, such as those made from alumina (Al₂O₃) or titanium dioxide (TiO₂), generally have good chemical stability, particularly when used in dry conditions. They are also more resistant to high temperatures and oxidation compared to organic aerogels.

Limitations: Some metal oxide aerogels can be sensitive to certain chemical environments, like strong acids or reducing agents, which may affect their stability.

4.Thermal Stability:

Aerogel tend to maintain their structure and properties at moderate temperatures, but they begin to degrade at higher temperatures, particularly organic aerogels, which tend to burn or decompose around 300–400°C. Silica aerogels, on the other hand, can generally withstand temperatures up to around 1000°C in dry air without significant decomposition.

In summary, aerogel is fairly chemically stable, but their stability is highly dependent on the composition of the aerogel and the environmental conditions to which they are exposed. They perform best in dry, neutral environments and can be susceptible to degradation under extreme conditions (high humidity, strong acids, or bases, etc.).