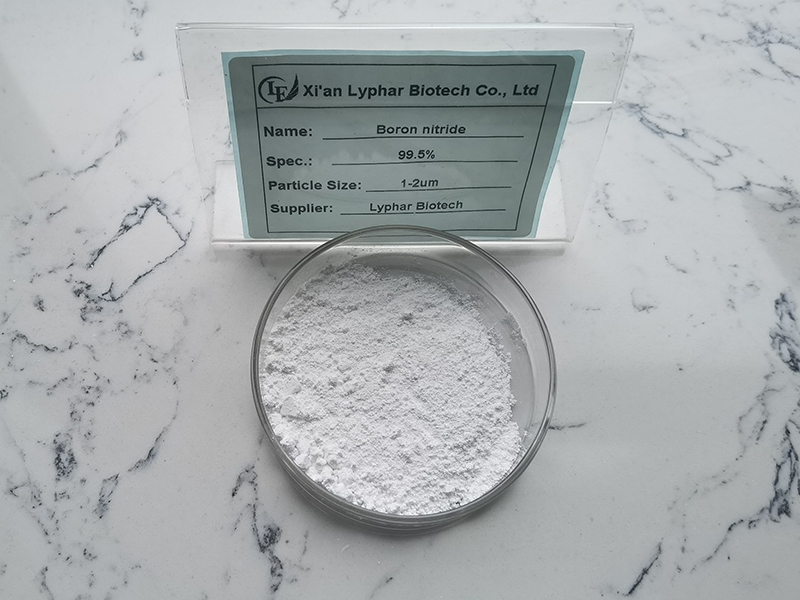

Boron Nitride (BN) is a versatile material and the way you use it depends on the form (Hexagonal Boron Nitride powder/flake, paste/coating, or Cubic Boron Nitride abrasive) and the application.

What form of boron nitride are we talking about?

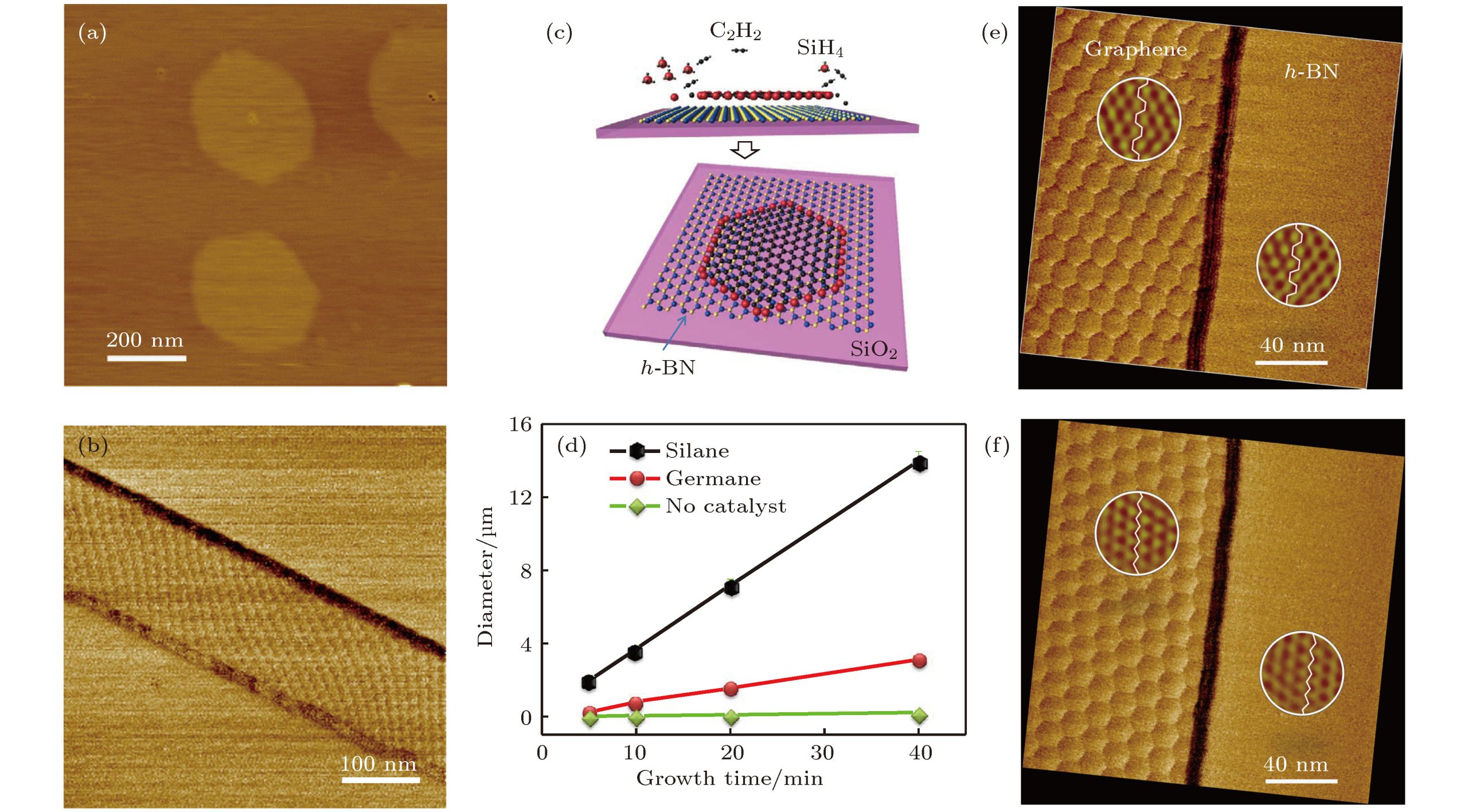

- Hexagonal Boron Nitride (h-BN) — flaky, lubricious, electrically insulating, thermally conductive; the “graphite-like” form used for lubricants, TIMs, cosmetic powders, fillers and high-temp release agents.

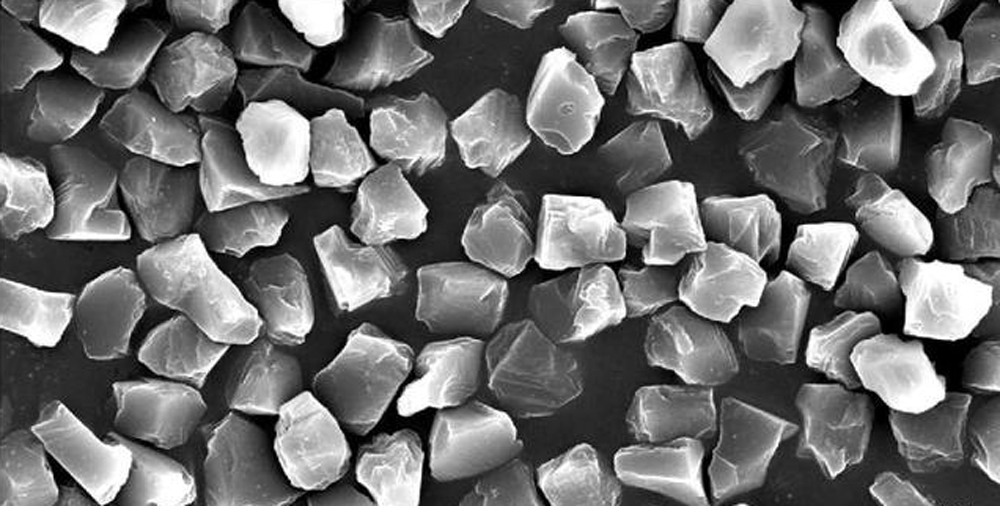

- Cubic Boron Nitride (c-BN) — superhard, used as abrasive grit and cutting tool material.

- Boron Nitride nanotubes / nanosheets / powders — specialty nanoforms used in research, electronics, composites.

Common uses and how to use it

1) As a high-temperature release agent / mold coating

- Use Hexagonal Boron Nitride powder or a spray formulation.

- Clean and dry the part/mold surface first.

- Apply a thin, even layer by brushing, spraying, or dusting. For sprays, follow manufacturer directions.

- Reapply between runs if parts begin to stick.

2) As a dry lubricant or lubricant additive

- Hexagonal Boron Nitride powder can be dusted onto mating surfaces or mixed into greases/fluids.

- For mixing: disperse slowly while agitating to avoid agglomerates; use a fine grade for smoother films.

- Use sparingly — thin films provide lubrication; thick pastes can attract dirt or impede motion.

3) As a thermal interface material (TIM) or thermal filler

- Boron Nitride (Hexagonal Boron Nitride flakes or particles) is blended into greases, silicones, or epoxies to improve thermal conductivity while keeping electrical insulation.

- Disperse with mechanical shear (stirrer, planetary mixer) and, when needed, mild heating to lower viscosity for uniform dispersion.

- Degas mixtures to remove trapped air before application.

- Apply a thin, continuous layer between heat source and sink; avoid air gaps.

4) In polymer/ceramic composites and coatings

- Add Boron Nitride as a filler to improve thermal conductivity, reduce friction, or enhance high-temperature stability.

- Pre-mix with the resin or use a coupling/dispersion agent if compatibility is poor.

- Control particle size and loading to balance mechanical and thermal properties.

5) As a sintering aid / crucible liner / powder processing

- Hexagonal Boron Nitride is used as a protective coating or release on graphite fixtures or for crucible liners due to chemical inertness and high-temp stability.

- Apply as an aqueous slurry or spray of Boron Nitride dispersion, then dry/bake per supplier instructions before use at high temperature.

6) As an abrasive or cutting material

- Cubic Boron Nitride is used in bonded abrasives and cutting tool inserts. This is industrial — use finished Cubic Boron Nitride tools rather than trying to handle raw grit unless you have industrial experience.

7) In cosmetics and personal care

- Cosmetic-grade ultra-fine Hexagonal Boron Nitride is used in powders and foundations to improve feel and oil control.

- Only use products and grades labeled cosmetic-grade and follow regulatory guidance and product formulation best practices.

Practical handling & mixing tips

- Use gradual addition of Boron Nitride into liquids/paints/greases while mixing to reduce clumping.

- Use appropriate mixers (magnetic stirrer, overhead stirrer, high-shear or planetary mixer) depending on viscosity and loading.

- When dispersing, consider a surfactant or dispersant compatible with your matrix if you see agglomeration.

Safety & storage

- Powder hazard: Boron Nitride is a fine powder — avoid inhaling. Use a dust mask or respirator (NIOSH/EN rated for particulates), gloves and eye protection when handling powders.

- Work in a ventilated area or local exhaust when generating dust.

- Cubic Boron Nitride and sharp particles can be abrasive — use appropriate PPE.

- Store dry, in sealed containers, away from strong oxidizers and moisture if specified by supplier.

Disposal

- Uncontaminated Boron Nitride is typically non-hazardous; follow local regulations.

- If contaminated with hazardous substances, dispose as hazardous waste per local rules.

When you need specifics

If you want a precise recipe, mixing speed/time, particle grade, or temperature profile, tell me:

- Which form of Boron Nitride you have (Hexagonal Boron Nitride powder, spray, paste, Cubic Boron Nitride, nano-Boron Nitride)?

- What application (thermal paste, lubricant, cosmetic, ceramic sinter, coating, abrasive tool)?

- Any constraints (max temperature, electrical insulation required, solvent or polymer type)?

I’ll give a tailored step-by-step procedure and safety checklist.