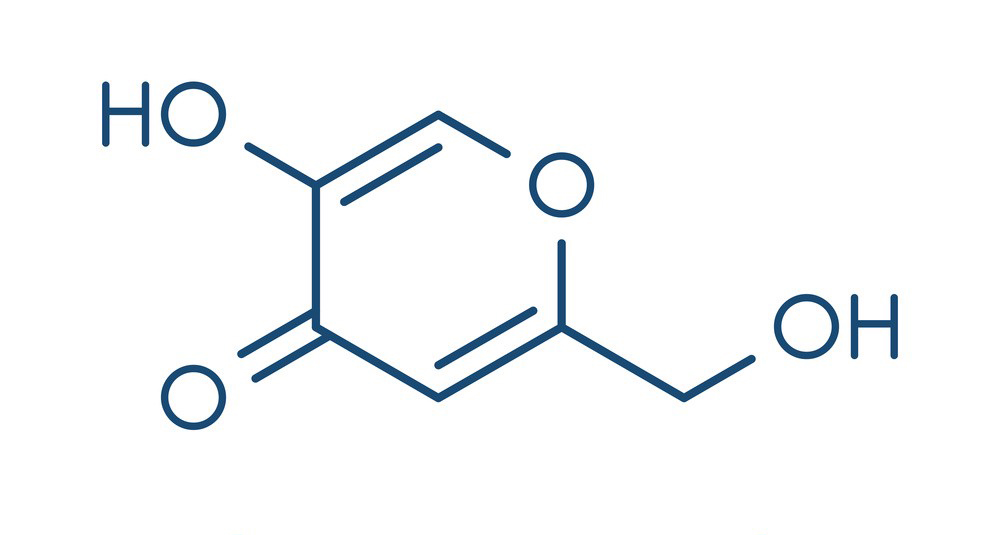

Kojic acid is a natural compound that is commonly used in the cosmetic and pharmaceutical industries for its skin-lightening and antioxidant properties. It is derived from various fungi, especially Aspergillus oryzae, and can also be found in certain foods like soy sauce and rice wine. The process of obtaining Kojic acid involves fermentation and extraction. Here is a simplified overview of the Kojic acid processing process:

1.Fermentation:

- Start with a suitable strain of Aspergillus oryzae or another Koji fungus.

- Provide a growth medium that contains ingredients like rice, wheat, or other starchy materials, as well as minerals and nutrients.

- Inoculate the medium with the fungus and allow it to grow under controlled conditions, including temperature, humidity, and aeration. During fermentation, the fungus produces Kojic acid as a metabolic byproduct.

2.Harvesting:

- Monitor the fermentation process to ensure that Kojic acid production is optimal.

- When the fermentation is complete (typically after several days), the culture is harvested.

3.Extraction:

- The harvested culture is subjected to extraction to separate the Kojic acid from the solid components, including the fungal biomass.

- One common method for extraction involves using a solvent like ethanol or ethyl acetate to dissolve Kojic acid selectively. The mixture is then filtered to remove solid impurities.

4.Concentration and Purification:

- The solvent containing Kojic acid is concentrated to increase the Kojic acid content.

- Purification techniques such as crystallization or chromatography may be used to further refine the Kojic acid and remove impurities.

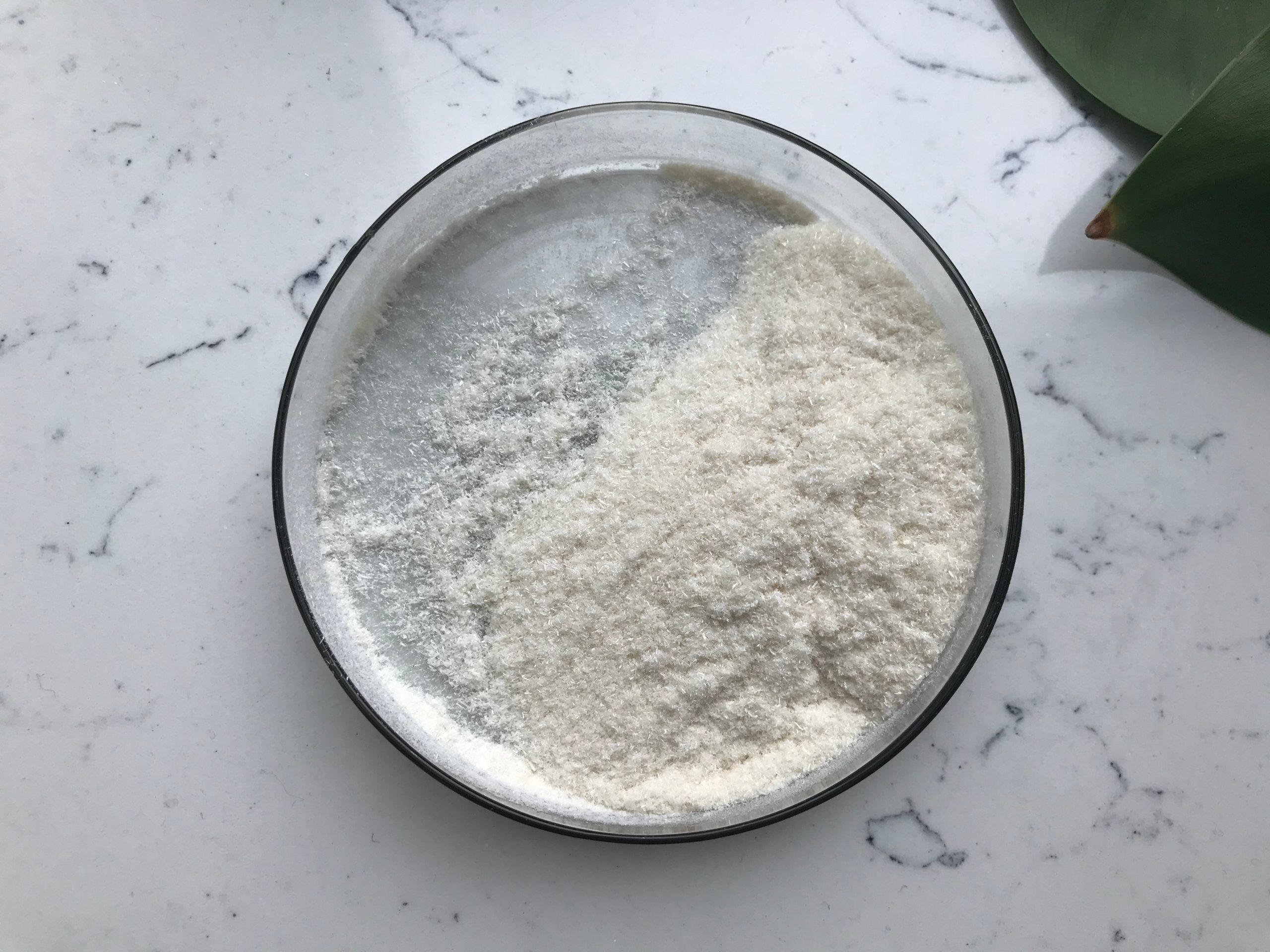

5.Drying:

- The purified Kojic acid solution is dried to obtain a solid form of Kojic acid.

- This can be achieved through methods like spray drying or vacuum drying.

6.Quality Control:

- The final product undergoes quality control testing to ensure it meets purity and safety standards.

- Testing may include assays for Kojic acid content, as well as checks for impurities and contaminants.

7.Packaging:

- The Kojic acid is packaged in suitable containers for distribution and use in various applications, such as skincare products, cosmetics, or pharmaceuticals.

It’s important to note that the specific details of the Kojic acid processing process can vary depending on the manufacturer, and there may be variations in the fermentation and extraction methods used. Additionally, safety and quality control are critical aspects of the process to ensure the final product is suitable for its intended applications.