Nattokinase capsules contain an enzyme called nattokinase, which is derived from a traditional Japanese fermented soybean dish called natto. Nattokinase has gained attention for its potential health benefits, particularly in supporting cardiovascular health due to its ability to break down fibrin, a protein involved in blood clot formation.

Here’s a general outline of the materials and methods typically involved in the production of nattokinase capsules:

1.Raw Materials:

Natto: Non-GMO soybeans are typically used for fermentation to produce natto.

Enzymes: Bacillus subtilis is the bacteria responsible for fermenting soybeans and producing nattokinase.

Capsule Ingredients: Usually composed of gelatin or a suitable vegetarian alternative for encapsulating the nattokinase powder.

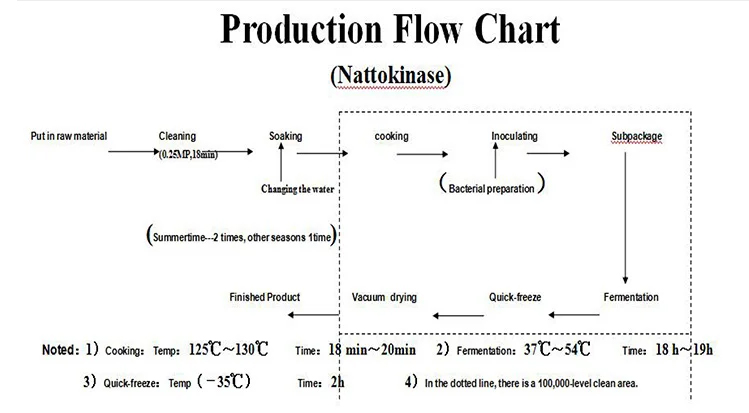

2.Fermentation:

Soybeans are steamed and then inoculated with Bacillus subtilis culture.

The inoculated soybeans are allowed to ferment at a controlled temperature and humidity for a specific period, usually around 24-48 hours.

During fermentation, Bacillus subtilis produces nattokinase as well as other beneficial compounds.

3.Extraction and Purification:

After fermentation, the natto is processed to extract the nattokinase enzyme.

Extraction typically involves filtration to separate the solid components of the natto from the liquid containing the enzyme.

The extracted liquid is then purified through methods such as centrifugation, chromatography, or precipitation to isolate the nattokinase enzyme.

4.Drying:

The purified nattokinase enzyme is usually in liquid form after extraction. It needs to be dried to form a powder suitable for encapsulation.

Spray drying or freeze-drying are common methods used to remove moisture and convert the liquid enzyme into a powder form while preserving its enzymatic activity.

5.Encapsulation:

Once the nattokinase powder is obtained, it is mixed with other excipients if necessary to improve flow properties and ensure proper dosing.

The nattokinase powder is then encapsulated into gelatin or vegetarian capsules using encapsulation machines.

Capsules are filled with the appropriate dosage of nattokinase powder, usually measured in milligrams.

6.Quality Control:

Throughout the manufacturing process, quality control measures are implemented to ensure the potency, purity, and safety of the nattokinase capsules.

This includes testing the raw materials, monitoring fermentation conditions, conducting assays to measure enzyme activity, and performing microbiological tests to ensure the absence of harmful contaminants.

7.Packaging and Labeling:

Once the capsules are filled and quality checked, they are usually packaged in bottles or blister packs.

Labels on the packaging provide information about dosage instructions, ingredients, expiration date, and any relevant warnings or precautions.

It’s important to note that specific details of the manufacturing process may vary between different manufacturers and formulations of nattokinase capsules. Additionally, adherence to regulatory standards and guidelines for dietary supplements is crucial to ensure the safety and efficacy of the final product.