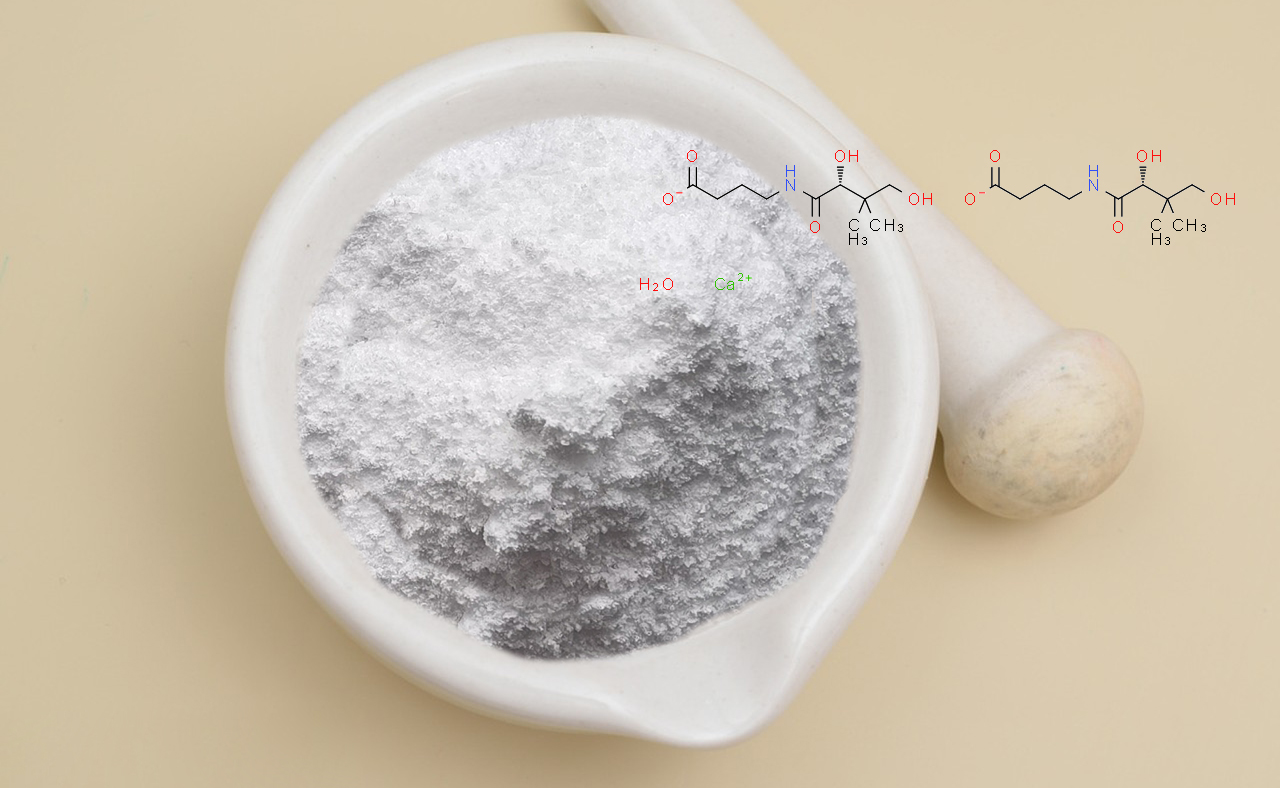

Calcium Hopantenate Hemihydrate is a calcium salt derivative of hopantenic acid, commonly known as pantogam. It is recognized for its neuroprotective properties and is utilized in various pharmaceutical applications.

Materials of Calcium Hopantenate Hemihydrate:

- Hopantenic Acid (Pantogam): The active pharmaceutical ingredient, known for its cognitive enhancement and neuroprotective effects.

- Calcium Source: Typically, calcium hydroxide or calcium chloride is used to form the calcium salt.

- Solvent: Purified water or an appropriate aqueous solution to facilitate the reaction.

Methods of Calcium Hopantenate Hemihydrate:

1. Preparation of Reactants:

- Dissolve hopantenic acid in purified water to achieve a clear solution.

- Prepare a separate aqueous solution of the chosen calcium source.

2. Reaction:

- Slowly add the calcium solution to the hopantenic acid solution under continuous

- Maintain the reaction mixture at a controlled temperature to ensure complete reaction and formation of calcium hopantenate.

3. Formation of Hemihydrate:

- Adjust the concentration and temperature conditions to promote the crystallization of calcium hopantenate hemihydrate.

- Isolate the hemihydrate crystals by filtration.

4. Drying and Milling:

- Dry the isolated product under controlled conditions to achieve the desired moisture content, ensuring the hemihydrate form is maintained.

- Mill the dried product to obtain a uniform powder with the required particle size distribution.

These steps outline a general approach to synthesizing Calcium Hopantenate Hemihydrate. Specific conditions such as pH, temperature, and reaction times may vary based on proprietary methods and desired product specifications. For detailed protocols, consulting specialized pharmaceutical manufacturing references or patents is recommended.