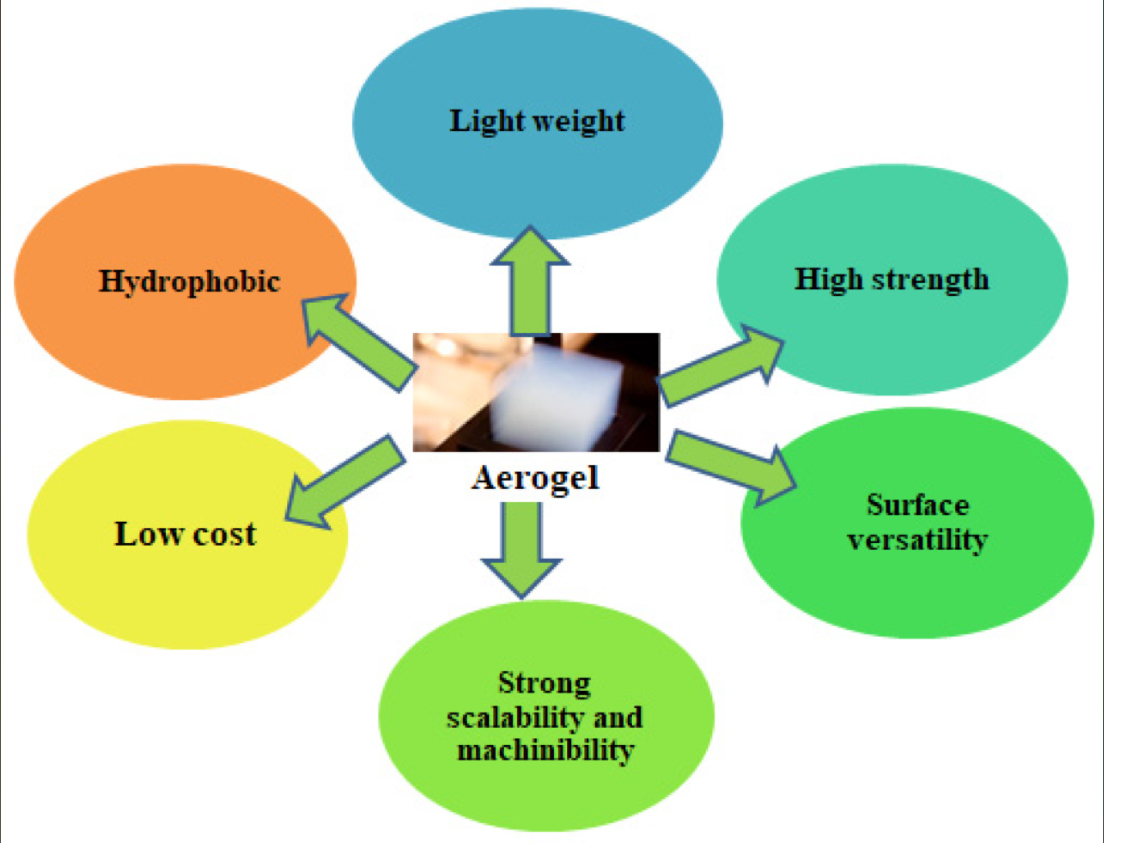

Aerogel is fascinating materials known for their extremely low density and unique mechanical properties. They are often described as “frozen smoke” due to their lightweight nature, but they also have remarkable performance in specific applications. Here are some key mechanical properties of aerogel:

- Low Density: Aerogel is among the lightest solid materials, with densities as low as 0.001 g/cm³ (for silica aerogel), making them ideal for applications where weight is a crucial factor, such as in aerospace and insulation.

- High Porosity: Aerogel is highly porous, often around 90-99% air by volume. This contributes to their low density but also impacts their mechanical strength.

- Brittleness: While aerogel is lightweight, they are typically brittle and can fracture easily under stress or impact. They lack the ductility seen in metals or plastics, so they require careful handling.

- Compressive Strength: Aerogel generally have low compressive strength, but this can vary depending on the type of aerogel. Silica aerogels, for example, tend to have compressive strengths in the range of 0.1–10 MPa, depending on their density and the manufacturing process.

- Elastic Modulus: The elastic modulus of aerogel is relatively low compared to traditional materials, indicating that they deform more easily under stress. For example, silica aerogels can have elastic moduli ranging from 10 MPa to 1 GPa.

- Tensile Strength: Aerogel is generally weak in tension, and their tensile strength is lower than that of many other materials, though some aerogels (such as polymer-based ones) can exhibit higher strengths than traditional silica-based aerogels.

- Thermal and Acoustic Insulation: While not strictly mechanical properties, aerogel is known for their excellent thermal and acoustic insulating properties. This is due to their extremely low thermal conductivity, which is primarily a result of their high porosity and low density.

- Fracture Toughness: Aerogel typically have low fracture toughness, meaning they tend to crack or break easily under impact or stress, especially in compression or bending.

Improving Aerogel Mechanical Properties:

Researchers have been working on reinforcing aerogel to improve their mechanical properties. This is often done by incorporating fibers, nanomaterials, or using composite structures. These can enhance their strength, flexibility, and overall durability.

Would you like to explore a specific type of aerogel, or perhaps applications where these mechanical properties are critical?