Boron Nitride exists in several forms—Hexagonal Boron Nitride (h-BN), Cubic Boron Nitride (c-BN), Wurtzite Boron Nitride (w-BN), and Amorphous Boron Nitride (a-BN). The synthesis method strongly influences which phase is produced.

1. Direct Reaction of Boron and Nitrogen

Method

Heat elemental boron with nitrogen gas (N₂) or ammonia (NH₃) at high temperature.

Reaction

- With nitrogen: 2B + N₂ → 2BN

- With ammonia: B + NH₃ → BN + 3/2 H₂

Conditions

- Temperature: 1000–1500 °C

- Atmosphere: N₂, NH₃, or vacuum

- Used mainly for Hexagonal Boron Nitride (h-BN) synthesis.

Advantages

- Simple and relatively low-cost

- Produces high-purity Boron Nitride (BN)

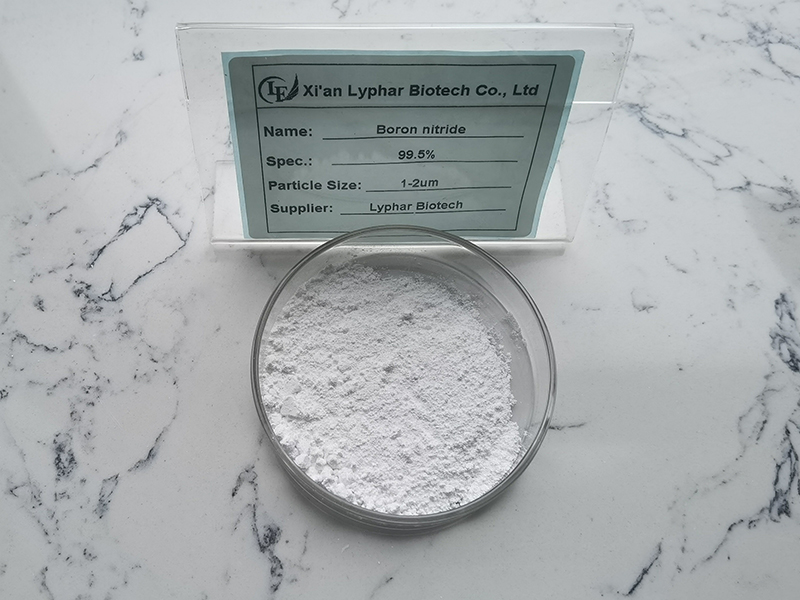

2. Reaction of Boron Oxide with Ammonia or Nitrogen

This is one of the most common industrial methods.

Reaction

- Convert boric acid → boron oxide: 2 H₃BO₃ → B₂O₃ + 3 H₂O (dehydration)

- React B₂O₃ with ammonia: B₂O₃ + 2 NH₃ → 2 BN + 3 H₂O

Conditions

- Temperature: 900–1200 °C

- Atmospheric or flowing NH₃

Advantages

- Uses inexpensive precursors

- Good for mass production of Hexagonal Boron Nitride (h-BN) powder

3. Carbothermal Reduction–Nitridation

Method

Mix boron oxide (B₂O₃) with carbon and heat in nitrogen.

Reaction

B₂O₃ + 3C + N₂ → 2BN + 3CO

Conditions

- Temperature: 1400–1800 °C

Advantages

- Low-cost and scalable

- Common for industrial Boron Nitride powder

Disadvantages

- Carbon contamination may occur

4. Chemical Vapor Deposition (CVD)

Used to make thin films of high-quality Boron Nitride.

Precursors

- BCl₃ + NH₃

- B₂H₆ + NH₃

- B-trichloroborazine (B₃N₃Cl₃)

General Reaction

BCl₃ + NH₃ → BN + 3HCl

Conditions

- Temperature: 600–1200 °C

- Used to make: Hexagonal Boron Nitride (h-BN) films, coatings, 2D Boron Nitride (“white graphene”)

Advantages

- High-purity, uniform films

- Suitable for electronics and coatings

5. Solvothermal or Polymer-Derived Ceramic (PDC) Method

Use borazine (B₃N₃H₆) or polyborazylene precursors.

Steps

- Polymer formation (cross-linking)

- Pyrolysis at ~1000 °C

- Crystallization into Boron Nitride (BN)

Advantages

- Produces high-purity Hexagonal Boron Nitride (h-BN)

- Good control over morphology (fibers, spheres, nanosheets)

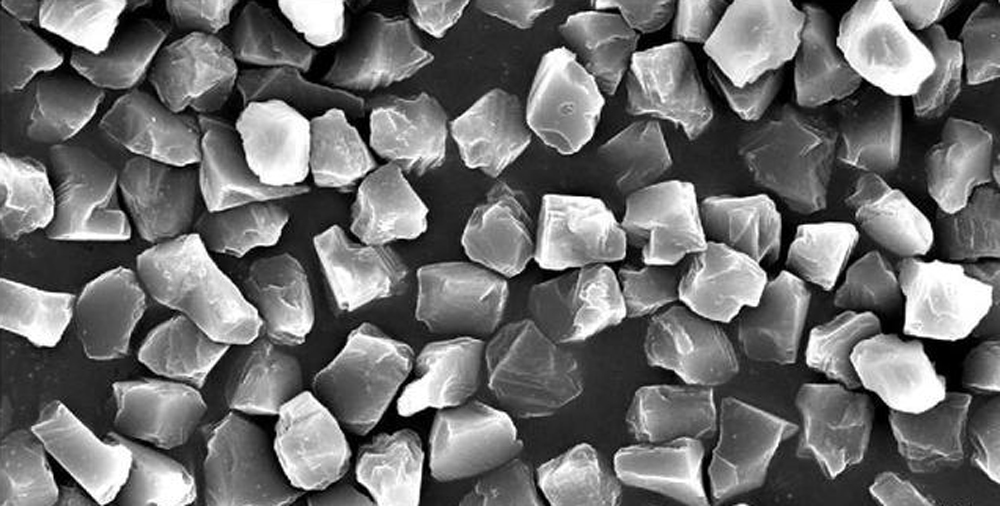

6. High-Pressure High-Temperature (HPHT) Synthesis — For Cubic Boron Nitride (c-BN)

Cubic Boron Nitride (c-BN) requires extreme conditions similar to diamond synthesis.

Method

Heat Hexagonal Boron Nitride (h-BN) under:

- Pressure: 5–7 GPa

- Temperature: 1500–2000 °C

- Catalyst: alkali metals, nitrides, or carbonates

Reaction

- Hexagonal Boron Nitride (h-BN) → Cubic Boron Nitride (c-BN) (phase transformation)

Products

Cubic Boron Nitride (c-BN) (superhard material comparable to diamond)

Summary Table

| Boron Nitride(BN) Form | Common Method | Key Conditions |

| Hexagonal Boron Nitride (h-BN) | Direct nitridation, B₂O₃ + NH₃, CVD, polymer-derived | 900–1500 °C |

| Cubic Boron Nitride (c-BN) | HPHT transformation | ~5–7 GPa, 1500–2000 °C |

| Boron Nitride (BN) Films | CVD, PVD, ALD | 600–1200 °C |