Boron Nitride (BN) exists in several polymorphs (most commonly Hexagonal Boron Nitride — h-BN, plus Cubic Boron Nitride — c-BN, Wurtzite Boron Nitride — w-BN, and various amorphous/nanostructured forms). Below I’ll summarize the major synthesis routes, typical conditions (ranges), advantages/limitations, and common characterization methods so you can pick the right route for your target Boron Nitride type and scale.

1) Routes by product type

Hexagonal Boron Nitride (h-BN) — bulk / powders / films / nanosheets

1. Direct nitridation (gas-solid)

- Method: nitridation of boron/boron oxide using ammonia (NH₃) or nitrogen sources at high temperature.

- Typical conditions: 900–1600 °C in flowing NH₃ or N₂/NH₃ mixtures; reaction time and ramp depend on particle size.

- Pros: simple, scalable for powders; inexpensive precursors.

- Cons: may produce oxygen-containing impurities if B₂O₃ is present; requires high T for good crystallinity.

2. Polymer-derived ceramics (PDC) / precursor pyrolysis

- Method: synthesize boron-nitrogen polymer (e.g., polyborazylene, polyborazine), then pyrolyze under inert/amine atmosphere to form Boron Nitride.

- Typical conditions: pyrolysis 800–1200 °C; allows shaping before conversion.

- Pros: good control of composition, useful for fibers/coatings and shaped parts.

- Cons: precursor synthesis required; organic byproducts must be handled.

3. Chemical vapor deposition (CVD) — films and 2D h-Boron Nitride

- Method: decompose boron-containing vapors (borazine, BCl₃ + NH₃, diborane + NH₃, etc.) onto heated substrates.

- Typical conditions: substrate temps commonly 800–1200 °C (depends on precursor). Low-pressure or atmospheric CVD variants exist.

- Pros: high-quality, uniform films and monolayer/bilayer control for electronics.

- Cons: needs careful precursor handling and substrate choice; process optimization required.

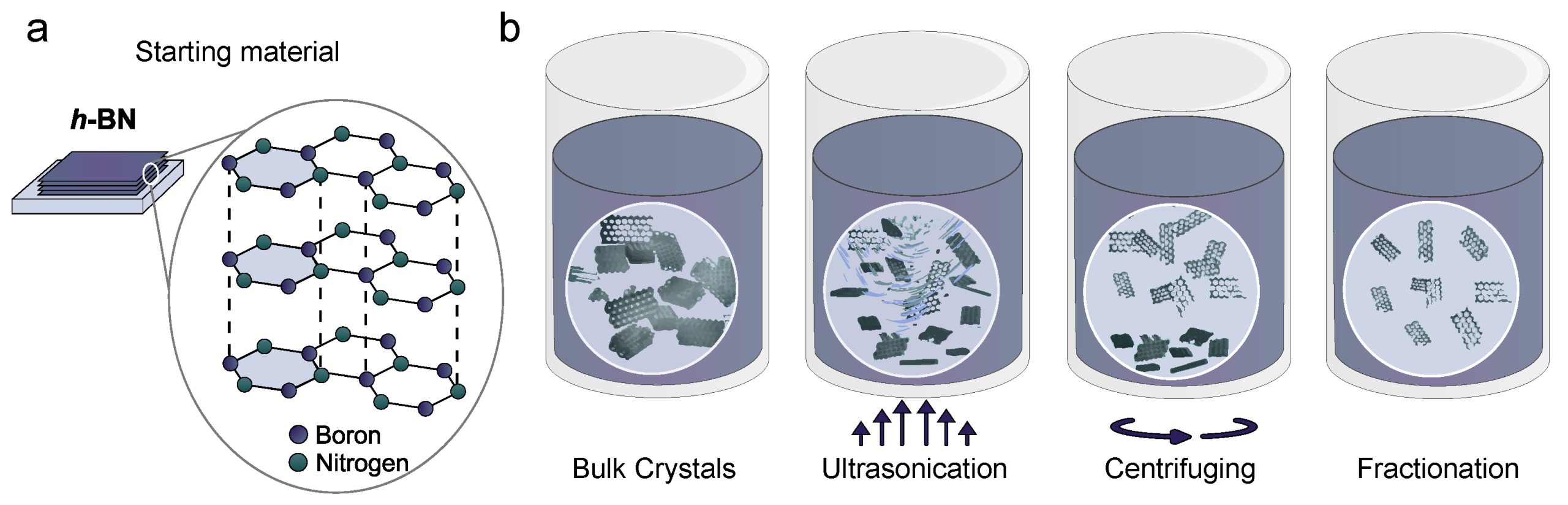

4. Liquid/solvothermal and precursor routes for nanosheets

- Method: solvothermal synthesis, exfoliation of bulk h-BN, or bottom-up reactions using precursors in autoclaves at modest temperatures (≤400 °C).

- Pros: lower temperature, can give nanosheets or nanoparticles.

- Cons: may require post-treatment to remove residues and improve crystallinity.

5. Ball-milling + annealing

- Method: mechanochemical mixing of boron/boron oxide with nitrogen source followed by thermal annealing.

- Pros: inexpensive, scalable for powders.

- Cons: defects and contamination from milling media; needs high-T anneal for crystallinity.

Cubic Boron Nitride (c-BN) and wurtzite Boron Nitride (w-BN) — superhard phases

High-pressure, high-temperature (HPHT) synthesis

- Method: convert h-BN or B + N precursors to sp³-bonded phases under extreme pressures and temperatures, often with catalysts.

- Typical conditions: very high pressures and temperatures (HPHT laboratory conditions).

- Pros: yields superhard c-Boron Nitride used industrially for cutting/grinding.

- Cons: requires specialized HPHT equipment and catalysts; not accessible in standard labs.

2) Typical precursors and reagents

- Boron sources: elemental boron, boron oxide (B₂O₃), boron halides (BCl₃), diborane (B₂H₆), borazine or polyborazylene (B₃N₃H₆ and derivatives).

- Nitrogen sources: ammonia (NH₃), molecular N₂ (less reactive), borazine (both B and N), urea/amine precursors (in solvothermal).

- Catalysts / additives (process dependent): metal substrates or seeds in CVD; for HPHT conversion metallic catalysts are used (industrial c-BN routes).

3) Typical processing parameters (guideline ranges)

- Temperature: 400 °C (solvothermal/exfoliation) → 800–1600 °C (pyrolysis/nitridation/CVD) → much higher + high pressure for c-BN/w-BN.

- Atmosphere: inert (Ar, N₂) or reactive (NH₃, NH₃/H₂ mixtures); oxygen must be excluded for high-purity Boron Nitride.

- Pressure: near atmospheric for most CVD and nitridation; elevated pressure only for HPHT c-Boron Nitride synthesis.

- Time: minutes–hours (CVD film growth); hours for bulk nitridation/pyrolysis; depends on thickness/crystallinity target.

4) Key practical considerations

- Purity control: remove boron oxide or oxygen contamination by using dry precursors and inert atmospheres; post-annealing in NH₃ can reduce oxygen.

- Crystallinity vs. defects: higher temperature and longer anneal improve crystallinity but can increase grain growth (affects nanosheet yield).

- Substrate choice (CVD): metals (Cu, Ni) or transition metal foils are common for 2D h-BN growth; insulating substrates require a transfer step.

- Scale: powder production (nitridation, PDC routes) scales well; large-area monolayer films require optimized CVD reactors.

5) Characterization methods

- X-ray diffraction (XRD): phase identification (h-BN peaks vs c-BN).

- Raman spectroscopy: h-BN E₂g mode (~1366 cm⁻¹ for high-quality h-BN).

- TEM / SEM: morphology, layer count, crystal defects.

- XPS / FTIR: chemical bonding, impurities (oxygen, carbon).

- AFM: thickness of 2D flakes/films.

6) Common applications tied to synthesis choice

- High-quality 2D h-BN (electronic/insulator layers): low-pressure CVD with borazine or BCl₃/NH₃ on metal substrates.

- Bulk powders, lubricants, cosmetics: large-scale nitridation or PDC routes.

- Superhard tooling (c-Boron Nitride): HPHT synthesis in specialized facilities.

- Ceramic composites & coatings: polymer-derived Boron Nitride coatings and powder additions.

7) Safety & environmental notes

Handle NH₃, BCl₃, diborane, and boron halides with appropriate gas-handling systems and scrubbing. These are toxic/corrosive and in some cases pyrophoric (diborane). Use proper ventilation, gas monitors, and PPE.

- Waste: acidic/corrosive byproducts (from halides) must be neutralized and disposed of per regulations.